Main test features:

Main test features:

Following tests can be performed on the HVAC test benches:

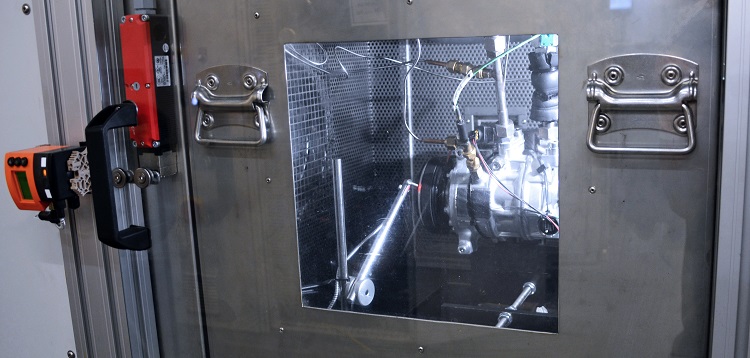

Heat exchanger Test Bench

The bench for oil-free AC condenser/heat exchangers performance measuring.

The Test Facility allows testing of various automotive AC condensers/heat exchangers under realistic environmental conditions. Its oil-free AC loop guarantee a precise condenser performance determination without the negative impacts of oil to the heat transfer.

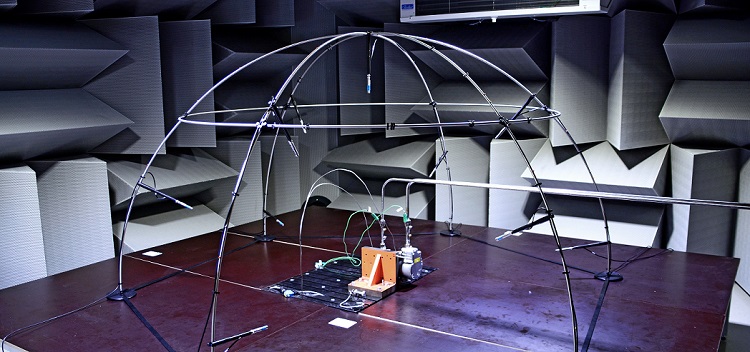

NVH Test Facilities

At SANDEN GmbH in Bad Nauheim we have Test Facilities to measure the Acoustic, Vibration, Pressure Pulsation, Sound Power and Forces of AC components, AC systems as well as full vehicles (combustion engine, hybrid, electric engine). Furthermore we can measure the NVH behavior of other components and devices as well as the Modal Modes and Operational Deflection Shapes.

On the following table there are the specifications of the different NVH chambers:

Semi Anechoic Chamber for component testing

Chamber size: 5,1m x 4,1m x 2,6m (l x w x h)

Classification: Class 1 according ISO 3745 with cut off frequency 100 Hz

Additional equipment: AC Load-units for R744, R1234yf, R134, Belt Drive (30 kW E-Motor)

Studio Bench for component testing

Chamber size: 3,0m x 2,9m x 2,3m (l x w x h)

Classification: Class 2 according ISO 3745

Additional equipment: AC Load-units for R744, R1234yf, R134, Belt Drive (24 kW E-Motor)

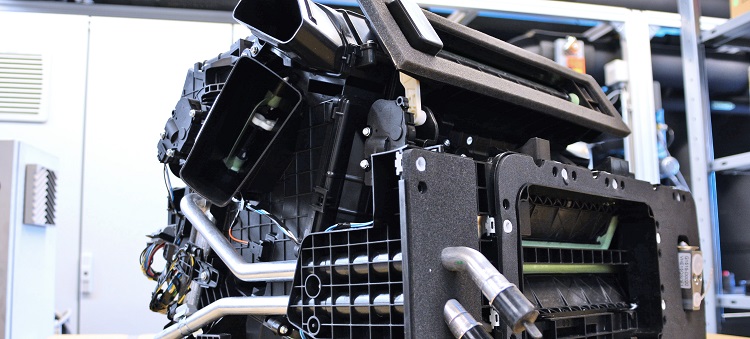

AC-System Testing

The perfect choice for in-depth Oil Management Investigations and Measuring of System COP [Coefficient of Performance] of a Mobile Air Conditioning System.

The Test Facility allows testing of various complete automotive AC circuits under realistic environmental conditions. Thanks to its modular structure the AC System Bench is capable to test all kind of AC systems. From a truck AC circuit to a state of the art BEV heat pump system.

This versatility is realized by three independent air-conditioning modules, two independent coolant-conditioning modules, high voltage power supplies for PTC heaters and compressor drive solutions for mechanical and electrical driven compressors.

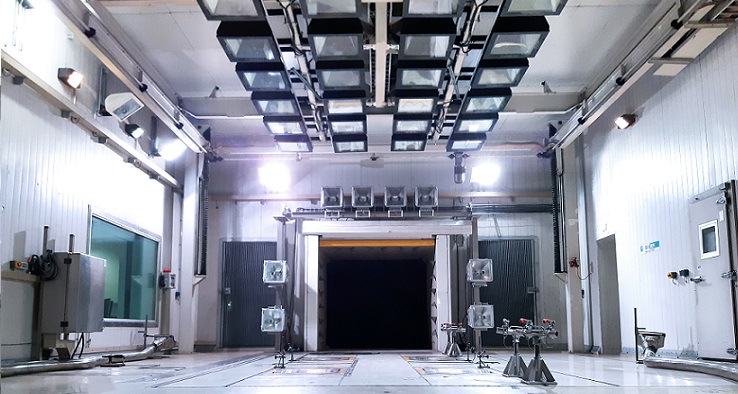

Climate Wind Tunnel

Climate Wind Tunnel provides testing opportunities at different weather conditions, such as desert climate at 50°C and 1000 W/m2 sun radiation, tropical conditions at 40°C and 85% humidity or arctic temperatures of -30°C. Additionally wind speed can be adjusted up to 160 km/h and all-wheel drive is available for vehicle tests (both cars and trucks).

NVH Test Facilities

At SANDEN GmbH in Bad Nauheim we have Test Facilities to measure the Acoustic, Vibration, Pressure Pulsation, Sound Power and Forces of AC components, AC systems as well as full vehicles (combustion engine, hybrid, electric engine). Furthermore we can measure the NVH behavior of other components and devices as well as the Modal Modes and Operational Deflection Shapes.

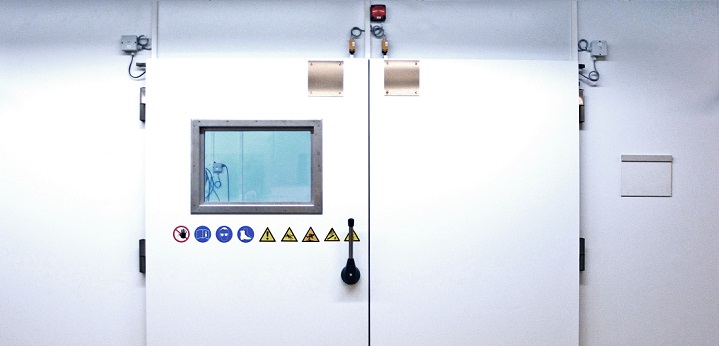

Semi Anechoic Chamber for full vehicle testing

Chamber size: 10,5m x 7,5m x 4,5m (l x w x h)

Max. axle load: 2500 kg

Temperature range: 0°C … 50°C

Humidity range: 15%rH … 80%rH

Classification: Class 1 according ISO 3745 with cut off frequency 70 Hz

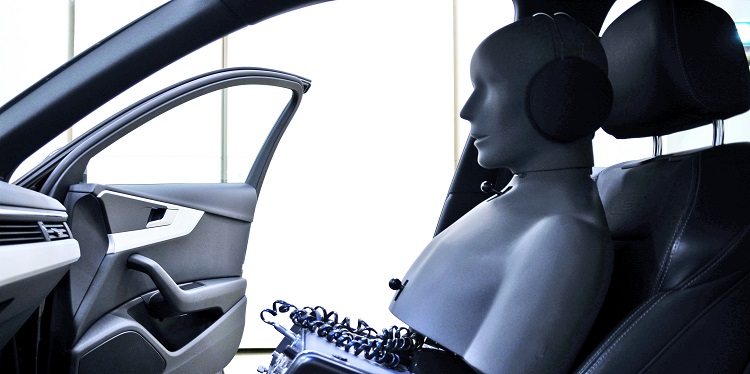

Vehicle Workshop

As part of the testing department the main duty of the vehicle workshop is to set up and prepare cars for tests in the climate wind tunnel and the NVH vehicle chamber.

When preparing vehicles for the CWT various sensors like thermocouples and pressure sensors have to be installed and for NVH tests for example pulsation and vibration sensors are required for testing. To install these sensors often it is necessary to solder adapters into the a/c lines and if this is not possible other ways have to be found to position the instrumentation at the measuring points.

Due to these requirements the personnel of the vehicle workshop has many years of experience as car technicians and has extensive know-how in setting up vehicles for long or short term tests.